Here's the abstract for a recently finished Master of science thesis by Farhood Delijani, University of Manitoba. Farhood posted a link to share on the Fabric Formwork Facebook group that you are so welcome to join.

The title of the thesis is: The Evaluation of Changes in Concrete Properties Due to Fabric Formwork

The work confirmed that fabric formwork is structurally safe alternative for forming reinforced concrete columns. The abstract found here goes like this:

"Fabric as a flexible formwork for concrete is an alternative giving builders, engineers, and architects the ability to form virtually any shape. This technique produces a superb concrete surface quality which requires no further touch up or finishing. Woven polyole-fin fabrics are recommended for this application.

A permeable woven fabric allows excess water from the concrete mix to bleed through the mold wall, and therefore reduce the water-cement ratio of the concrete mix. Due to the reduction in water-cement ratio, higher compressive strength in fabric formed concrete may be achieved, as also suggested by earlier research.

The current research study was conducted to investigate and document the changes in concrete strength and overall quality due to use of commercially available woven polyolefin fabrics. Use of fabric formwork will contribute to decreased construction cost, construction waste, and greenhouse gas emissions.

Two sets of tests were conducted as a part of this research study including comparison of compressive strength of fabric formed versus PVC formed concrete cylinders and comparison of be-haviour of the fabric formed reinforced columns versus cardboard formed reinforced concrete columns. Variables in this research were limited to two types of fabric with dif-ferent permeability (Geotex 104F and Geotex 315ST) and two types of concrete; concrete made with conventional Portland cement and no flyash herein called normal concrete (NC) and concrete with 30 percent flyash in its mix design (FAC).

The laboratory results revealed that fabric Geotex 315ST is an ideal geotextile for forming concrete. It was also found that the effects of fabric formwork on concrete quality in a large member are limited mostly to the surface zone and the core of the concrete remains the same as a conventionally formed concrete.

Even though fabric formed cylinder tests showed an average of 15% increase in compressive strength of the concrete samples, compressive strength of the reinforced columns did not dramatically change when com-pared to the companion cardboard formed control columns.

This research confirmed that fabric formwork is structurally safe alternative for forming reinforced concrete columns."

Congratulations to Farhood on his degree! It will be interesting to see if the fabric forming community will see more interesting work from him in the future.

Thursday, January 6, 2011

Thesis work on fabric formed concrete columns

Labels:

CAST,

fabric formwork

Fabric formed concrete benches

As a direct continuation of the previous post on an upcoming concrete workshop in which students will design and produce benches, here's another couple of examples. Bench could be read as just another word for span - it's just a matter of scale, whether the span holds a person or a floor, right?

[Image of fabric formed beam - could be used as bench, by CAST at University of Manitoba, Canada]

Fabric formed beam - or bench

Above image is cast as a beam of 22 metres. - I've sat on it, so you could use it as a bench, I guess - What's interesting about this piece when it comes to producing a long span is the fact that it was cast in just two flat sheets of fabric!

The beam is actually quite old and the good people at CAST (very firgurative abreviation for Centre for Architectural Structures and Technology at the University of Manitoba).

Do read more about the pioneering work at CAST and professor Mark West here.

Fabric formed furniture

The pieces of furniture by the Argentinian Grupo Bondi definitely look familiar. (see the post on the Ambiguous Chair here). The guys have been working with flexible molds for some years and, opposed to the research pieces done elsewhere, there's actually price tags on most items.

The bench weighs 145 kgs. The concrete mattress sits on iron legs and will fool you with the apparent upholstered bulges. Previous work could be shells? The cushion below is only 39 kgs according to the designers.

The stunning shell solution

I need to show you a more recent project from CAST. Ronnie Araya works there as an assistant Professor and did these beautiful thin shells that also have some spin off work for furniture. - the overall interest is architectural structures - but, as mentioned befor - working with technologies at a furniture scale is an interesting starting point - and something that is more likely to sooner have a life outside the studio than large load bearing structures.

I wrote more about this piece in this previous post

Read more about the stunning shell work at CAST here. The words is that the studio is doing a project with shells like these - so I guess work does get out of the lab! Can't wait to see it!

[Image of fabric formed beam - could be used as bench, by CAST at University of Manitoba, Canada]

Fabric formed beam - or bench

Above image is cast as a beam of 22 metres. - I've sat on it, so you could use it as a bench, I guess - What's interesting about this piece when it comes to producing a long span is the fact that it was cast in just two flat sheets of fabric!

The beam is actually quite old and the good people at CAST (very firgurative abreviation for Centre for Architectural Structures and Technology at the University of Manitoba).

Do read more about the pioneering work at CAST and professor Mark West here.

Fabric formed furniture

The pieces of furniture by the Argentinian Grupo Bondi definitely look familiar. (see the post on the Ambiguous Chair here). The guys have been working with flexible molds for some years and, opposed to the research pieces done elsewhere, there's actually price tags on most items.

The bench weighs 145 kgs. The concrete mattress sits on iron legs and will fool you with the apparent upholstered bulges. Previous work could be shells? The cushion below is only 39 kgs according to the designers.

[Concrete furniture by Grupo Bondi]

I bet that those pieces must have been cast in fabrics or similar flexible formwork. Do check out the web site for more design ideas cast in flexible formwork and products to order.The stunning shell solution

I need to show you a more recent project from CAST. Ronnie Araya works there as an assistant Professor and did these beautiful thin shells that also have some spin off work for furniture. - the overall interest is architectural structures - but, as mentioned befor - working with technologies at a furniture scale is an interesting starting point - and something that is more likely to sooner have a life outside the studio than large load bearing structures.

I wrote more about this piece in this previous post

[Image of rigid fabric formwork and the cast shell - I think this is a scale model in plaster. Image courtesy of CAST]

[Image of full scale PVC-coated mold ready to be cast with GFRC, Glass Fibre Reinforced Concrete, Photo from CAST].

Read more about the stunning shell work at CAST here. The words is that the studio is doing a project with shells like these - so I guess work does get out of the lab! Can't wait to see it!

Labels:

Design,

fabric formwork,

Flexible formwork,

Grupo Bondi,

Mark West,

Ronnie Araya

Concrete benches

These days I'm preparring a workshop for a large group of architecture and architectural engineering students. The materials given are concrete (but of course), fabric, plywood and laths. The assignment will be to designg and construct a bench. Several issues goes into this assignment - there's the functional and aesthetic part of designing a bench in concrete - and then there's a focus on the choice and use of materials if the aim is light weight, or spectacularly sculpted, there'll be some advanced geometries to figure out.

Well - much fun is awaiting for an intense workshop!! I found some images of concrete benches - and some made without concrete that might work as inspiration.

There's a point to make with regards to the choice of materials: namely, where and how is precision desired and obtained via clamps or the design of restraining devises - and where is the fabric allowed to work its ways and deflect under the load of concrete. - Another question is how to deal with the transition of the formwork to the uncovered surface.

Well - much fun is awaiting for an intense workshop!! I found some images of concrete benches - and some made without concrete that might work as inspiration.

There's a point to make with regards to the choice of materials: namely, where and how is precision desired and obtained via clamps or the design of restraining devises - and where is the fabric allowed to work its ways and deflect under the load of concrete. - Another question is how to deal with the transition of the formwork to the uncovered surface.

Light weight structures

Above images are all but heavy - and they are not cast in concrete but by laser cut metal. A concrete mind would imagine these these algorithmically generated patterns cast in high strength fibre reinforced concrete - and soon after scale the fellow to something a lot larger - Otherwise you might use a big cookie cutter and stamp your flat sheet of Eternit (fibre reinforced concrete mostly used for cladding) and make a perforated version of the award winning 'Dune' concrete chair below by Rainer Mutsch.

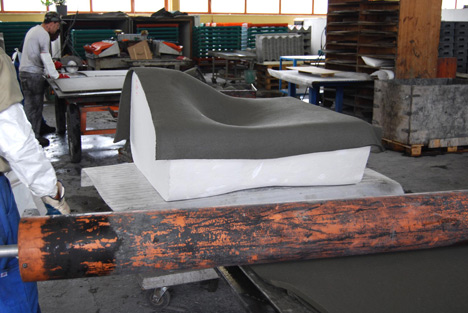

[The production of the Dune lounge chair at Eternit. Read more about it at this older post.

Post to be continued - now

This post was actually much more elaborated but my computer is having an off day and deleted most of it (sigh) - so - this post continues right away for some examples cast in fabrics - click here when ready.

Labels:

Arkitura,

Design,

Rainer Mutsch,

Zaha Hadid

Subscribe to:

Posts (Atom)