The guys have developed an adaptable formwork method using they good old pin-art principle, gotten themselves a client, and are underways towards a patent on their method.

Way to go - below are a few images from their web site - they will be guys to watch!

[Rendering of concrete shelter for Danish National Park Mols Bjerge]

[Rendering of the back side of the shelter showing signs of biological growth]

[Kinetic mould]

About the Kinetic MouldFrom the website we know:

"The concept of the flexible mould to make it economical sound to produce double curvature surface elements in different material directly from CAD software. The flexible mould can within minutes position it self to any possible shape which makes it ideal for high volume industrial production."

[The flexible mould process from design to construction]

"The flexible mould seeks to satisfy the growing market for free form surfaces which typically is a very expensive surface to construct" besides the aim is to "promote more advanced as well as interesting architecture thereby leaving behind the concept of flat tedious surfaces in architecture."

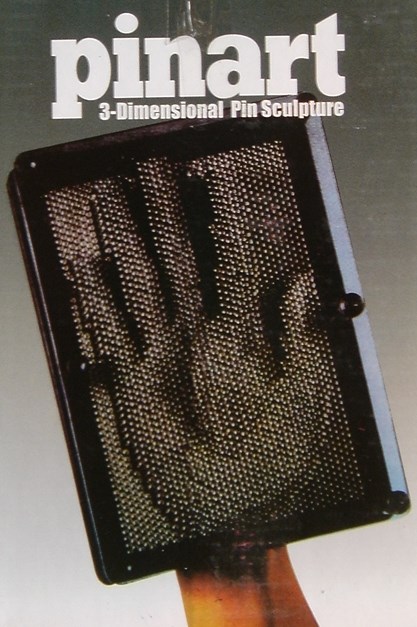

Pin art what?

The pin-art principle I referred to in the beginning of the post may ring a bell if you see this image below.

-or this movie of a performance on a large pinart frame at a kids' museum in Sheboygan, Wisconsin, USA

Check out the extremely related research by Roel Schipper at the TU Delft and Arno Pronk at the TU Eindhoven, both in the Netherlands:

ReplyDeletehttp://www.citg.tudelft.nl/live/pagina.jsp?id=1f4e105f-56d2-4a6c-934d-b383733c6ee5&lang=en&binary=/doc/250257_100707.pdf

http://www.arnopronk.com/bestanden/Double-curved%20surfaces%20using%20a%20membrane%20mould.pdf

That was me by the way, Diederik.

ReplyDeleteHighly relevant, indeed, Diederik. Thanx for sharing :) I think the patent must deal with the membrane that the Adapa guys have developed to smoothen the surface over the pins?

ReplyDeleteWhen will you guest blog here? - or launch your fabric formwork blog??